Why Water in the Bottom of Your Water Softener Isn’t Always a Bad Thing

Shop Our Products

Freedom RV Water Softener System

Specifically for RV and fifth-wheel owners, this high-quality system guarantees your RV’s water is pure,

Finding water in the bottom of your water softener’s brine tank can be puzzling and worrying. However, this isn’t always a cause for concern. Understanding the function of the brine tank and the reasons for water accumulation can help you determine whether there’s an issue that needs addressing. In this guide, we’ll break down everything you need to know about water in your brine tank.

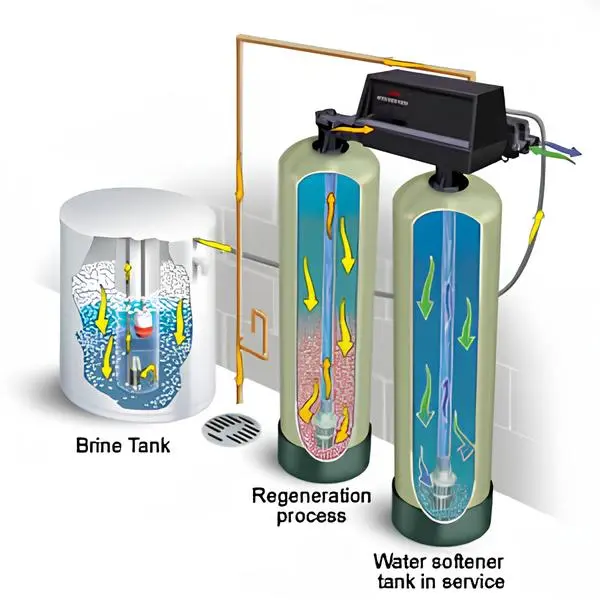

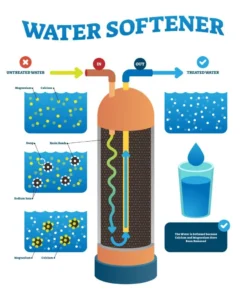

What is a Brine Tank?

A brine tank is a crucial component of a water softener system. It holds the salt solution (brine) that is used to regenerate the resin beads in the softener, which remove hardness minerals from your water. The brine tank works in conjunction with the resin tank to ensure your water remains soft and free of excess calcium and magnesium.

How Do Brine Tanks Work?

The brine tank’s primary function is to produce a brine solution that recharges the resin beads in the water softener. This process involves several steps:

- Fill Cycle: Water enters the brine tank to dissolve the salt, creating the brine solution.

- Brine Draw Cycle: The brine solution is drawn into the resin tank to regenerate the resin beads.

- Rinse Cycle: Fresh water rinses the resin tank, washing away hardness minerals and excess brine.

There Are 2 Types Of Brine Tanks

Wet Vs Dry Brine Tanks

| Feature | Wet Brine Tank | Dry Brine Tank |

|---|---|---|

| Water Presence | Always contains some water at the bottom | Only fills with water during regeneration |

| Maintenance Frequency | Requires more frequent monitoring and maintenance | Less frequent maintenance needed |

| Salt Efficiency | Requires more salt due to constant water presence | More efficient, requires less salt |

| Brine Solution Production | Continuous dissolution of salt to maintain brine solution | Brine solution is produced only during regeneration |

| Common Issues | Salt bridges, salt mushing, clogged drain lines | Residual water after regeneration, float valve issues |

| Water Level | Several inches of water, covering the salt | Mostly empty after regeneration, little to no standing water |

| Typical Problems | Improper dissolution, salt bridges, salt mushing | Float valve issues & residual water issues |

| Advantages | Consistent brine availability | More efficient, less salt waste |

| Disadvantages | Higher salt usage, more frequent maintenance | Requires careful timing of regeneration cycles |

Wet Brine Brines

A wet brine tank always has a certain amount of water at the bottom, which is used to dissolve the salt continuously. This type of tank requires more frequent monitoring and annual maintenance to ensure the brine concentration remains effective.

Dry Brine Brines

A dry brine tank only fills with water when it’s time to create the brine solution for regeneration. This system can be more efficient and requires less salt, but it also means the tank is usually empty between regeneration cycles.

Why Water May Be In Your Softener‘s Brine Tank?

There are several reasons why you might find water in the bottom of your brine tank:

- Normal Operation: In a wet brine tank, water at the bottom is normal and necessary for the system to function.

- Salt Bridge: A salt bridge occurs when hardened salt forms a crust above the water level, preventing proper dissolution and causing excess water to accumulate.

- Clogged Drain Line: A blockage in the drain line can prevent the system from properly flushing out the brine, leading to water buildup.

- Improper Settings: Incorrect settings on the water softener can result in too much water being added to the brine tank.

How Much Water Should Be There?

Water in the bottom of the brine tank is not always a problem. For wet brine systems, this is part of normal operation. Even in dry brine tanks, some residual water can remain after the regeneration cycle, which is typically harmless.

Wet Brine Tank

For a wet brine tank, it’s normal to have several inches of water at the bottom. This water level should be maintained to ensure there is always enough brine solution to regenerate the resin beads effectively. Typically, the water level should cover the salt, but not be excessively high.

Dry Brine Tank

In a dry brine tank, there should only be water during the regeneration cycle. After regeneration, the tank should be mostly empty, with little to no standing water. Any residual water should drain away, and the tank should remain dry until the next regeneration cycle.

When Standing Water Is a Big Deal

Keep in mind, there are instances when water in the brine tank can indicate a problem.Be mindful of the follow potential problems.

Common Issues to Look For

- Salt Bridges: If you notice hard, crusty salt formations, it might be preventing proper brine production.

- Salt Mushing: This occurs when salt dissolves into a sludge-like consistency at the bottom of the tank, blocking the system.

- Clogged Injector: A clogged injector can prevent the brine solution from being drawn into the resin tank, leading to water buildup.

- Float Valve Issues: Problems with the float valve can cause improper water levels in the brine tank.

Fixing Common Issues

Salt Bridges

- Break Up the Bridge: Use a broom handle or a similar tool to carefully break up the salt bridge.

- Monitor Salt Level: Regularly check and maintain the proper salt level to prevent future bridges.

Salt Mushing

- Clean the Tank: Remove the salt mush and clean the bottom of the brine tank thoroughly.

- Use High-Quality Salt: Switch to high-purity salt to minimize the risk of mushing.

Clogged Injector

- Inspect and Clean: Remove the injector and clean it with a soft brush and warm water.

- Replace if Necessary: If the clog persists, consider replacing the injector.

Float Valve Issues

- Check the Float Valve: Ensure the float valve moves freely and is not obstructed.

- Adjust the Float: Adjust the float to maintain the correct water level in the brine tank.

- Replace if Needed: If the float valve is damaged or malfunctioning, replace it with a new one.

How to Adjust Water Levels in the Brine Tank

Adjusting the water levels in your brine tank can help ensure your water softener operates efficiently:

- Check Salt Level: Ensure there is enough salt in the tank to produce an effective brine solution.

- Break Up Salt Bridges: Use a broom handle or similar tool to break up any salt bridges that may have formed.

- Clean the Tank: Periodically clean the brine tank to remove any salt mush or debris.

- Inspect the Float Valve: Make sure the float valve is functioning properly and adjust it if necessary.

How to Care for the Brine Tank

- Regular Cleaning: Clean the brine tank once a year to prevent salt buildup and sludge formation.

- Use High-Quality Salt: Using high-purity salt can help prevent issues like salt bridges and mushing.

- Monitor Salt Levels: Keep an eye on the salt levels and refill as needed to maintain proper brine concentration.

Learn why is water softener maintenance important.

Conclusion

Understanding why there is water in the bottom of your water softener’s brine tank can help you determine if it’s a normal part of operation or a sign of a problem. Wet brine tanks naturally contain water, while dry brine tanks should only have water during regeneration cycles. Regular maintenance and monitoring can prevent issues and ensure your water softener functions efficiently. If you encounter persistent problems, consulting a professional can help you address any underlying issues.

FAQ

Should there be standing water in my water softener?

Yes, standing water in your water softener can be normal, especially if you have a wet brine tank. This water is necessary for dissolving the salt to create the brine solution required for the regeneration process.

How full of water should my water softener be?

The water level in your water softener depends on the type of brine tank you have. A wet brine tank should have several inches of water covering the salt. In a dry brine tank, there should be little to no water after the regeneration cycle.

Should I fill my water softener all the way?

No, you should not fill your water softener all the way with water. Only the appropriate amount of water needed for the brine solution should be present, which varies by the type of brine tank. Overfilling can disrupt the system’s efficiency and function.

Share:

Talk to A Water Quality Expert

Shop Our Products

Freedom RV Water Softener System

Specifically for RV and fifth-wheel owners, this high-quality system guarantees your RV’s water is pure,

6 Tips on How to Choose A Water Softener

To choose the right water softener, consider your household size, water usage, water hardness, regeneration method, salt-based vs. salt-free systems, installation, and maintenance needs.

6 Things High Quality RV Water Softeners Always Have

A high-quality RV water softener should be compact, durable, easy to install and regenerate, compatible with RV plumbing systems, and highly efficient. This guide covers the essential features to look for when choosing the best portable water softener for your RV.

All 12 Pros & Cons of Salt vs. Salt Free Water Softeners

The main differences between salt and non-salt water softeners include their effectiveness at softening water, maintenance requirements, environmental impact, operational costs, and health considerations. This guide will help you understand these differences and decide which type of water softener is best for your needs.

Join Our

Newsletter

Get the latest information, and exclusive offers on water softening and purity solutions